The Rise of Connected Jobsite Technology: How Smart Tools Are Transforming Construction Management

For decades, progress on a construction site was measured by noise, movement, and sweat. A foreman’s instincts and a clipboard were enough to run a crew, and problems were solved face-to-face. Today that same jobsite hums with sensors, tablets, and wireless data streams. The conversation between people and machines now defines productivity. The construction industry is no longer about managing labor and materials alone—it’s about managing information.

A connected jobsite links every piece of the operation: the crew, the equipment, the drawings, and the client. Smartphones replace radios, dashboards replace filing cabinets, and live data replaces weekly reports. Contractors who once lost hours chasing paperwork now make decisions instantly, supported by clear, verifiable information gathered straight from the field.

The change began quietly with digital timecards and GPS tracking. Those early tools proved that real-time visibility could solve age-old problems like inaccurate labor logs and misplaced materials. Then came integrated project-management platforms that connected estimating, scheduling, and accounting. The modern jobsite has evolved into a digital ecosystem, where every photo, signature, and update is stored automatically in the cloud.

The Foundation of Connectivity

A connected jobsite begins with reliable communication. Without strong Wi-Fi or cellular coverage, even the best software fails. Many contractors now deploy portable network units or mesh routers that travel with the project. This infrastructure ensures that every device—from tablets to laser scanners—stays online. Once connectivity is stable, everything else follows: cloud storage, real-time collaboration, and instant updates between the field and office.

Connectivity does more than speed up messaging; it changes accountability. When everyone sees the same live data, misunderstandings fade. The field team knows exactly what version of the drawings they’re building from. The office can track progress and issue change orders immediately. Clients receive accurate updates with visual proof instead of vague reports. This transparency reduces rework, strengthens trust, and compresses the feedback loop that once caused endless delays.

Smart Tools for Smarter Work

The new generation of tools carries intelligence inside the handle. Cordless drills, saws, and torque wrenches now include embedded chips that record usage, temperature, and performance. These readings sync automatically to contractor dashboards, showing not only how often the tool is used but whether it’s being used safely. When a power tool overheats or approaches maintenance limits, the system sends an alert before failure occurs. The result is fewer breakdowns, lower replacement costs, and safer crews.

Beyond handheld devices, large machinery also communicates constantly. Excavators track hydraulic pressure, cranes monitor load limits, and generators report fuel efficiency. Instead of waiting for a problem to appear, equipment managers can view predictive alerts and schedule service precisely when needed. Downtime becomes a choice rather than an accident.

Data as the New Building Material

Every connected device creates data, and that data has become as valuable as the materials on the job. Time entries, tool logs, drone footage, and machine reports together form a digital twin of the project. Managers can compare actual performance against estimates in real time, identifying inefficiencies before they multiply. Historical data from past projects refines future bids, making each estimate more accurate than the last.

This data also powers collaboration across the entire supply chain. Architects, engineers, subcontractors, and owners work within shared platforms that update automatically. A design change approved in the architect’s office appears on every field tablet within seconds. The jobsite operates like a living network—adaptive, self-correcting, and transparent.

Cultural Change on the Connected Jobsite

Technology adoption is not only a technical challenge but also a cultural one. Crews who have built by experience for years may view new systems as unnecessary interference. Success comes when leadership communicates that technology isn’t replacing their expertise—it’s amplifying it. When foremen see that digital tools reduce rework, speed up payroll, and provide proof of performance, resistance fades. Over time, technology becomes as natural a part of construction as steel-toe boots and hard hats.

The companies thriving today aren’t necessarily the largest; they’re the most adaptive. They treat technology as part of craftsmanship. Precision doesn’t come from guessing or memory anymore—it comes from verified data, accessible anywhere, at any moment.

Real-Time Data and Automation — The Engine of Efficiency

The most powerful outcome of the connected jobsite is speed. Real-time data has turned construction from a reactive process into a predictive one. In traditional project management, updates came at the end of the day, week, or phase. By then, errors had already grown roots. With automation and live data, contractors can see those errors forming and correct them before they cost money. That single change—catching problems as they happen—creates the largest leap in efficiency the industry has ever seen.

Automation doesn’t replace human decision-making; it sharpens it. When systems track time, equipment usage, materials, and progress automatically, superintendents no longer chase information. They interpret it. The data tells them which crew is ahead, which is falling behind, and which machine needs service before it breaks down. A dashboard replaces a dozen phone calls, and those few saved hours per day multiply into thousands of dollars per project. Every task becomes measurable, and every delay visible in real time.

The transformation extends to materials and logistics as well. Automated delivery tracking ensures that supplies arrive just when needed, avoiding costly downtime or cluttered sites. Smart sensors embedded in concrete, steel, or asphalt provide live readings of curing, temperature, and strength. This allows quality control teams to make immediate decisions rather than waiting on lab results. A project that once stopped for testing can now move continuously, guided by live science at the jobsite level.

Real-time data also bridges the gap between the field and finance departments. Labor hours sync automatically to payroll, purchase orders link directly to budgets, and change orders are reflected in cost projections within minutes. The financial side of construction, once weeks behind actual production, now runs almost in parallel. Business owners can open a single dashboard and see cash flow, productivity, and risk exposure at that exact moment. This clarity eliminates surprises and supports decisions based on evidence rather than assumption.

Automation isn’t limited to reporting—it now extends to physical work. Machine control systems on excavators and graders use GPS and digital design models to guide operators with millimeter accuracy. Instead of relying on string lines and stakes, crews follow digital terrain maps visible right in the cab. The machine adjusts blade angles, depth, and slope automatically. Projects that once took multiple passes can now be completed in one, reducing fuel and labor costs. These precision systems not only speed up grading and paving but also improve safety by limiting the need for workers near heavy moving machinery.

As more contractors adopt automation, data standards are becoming the new language of the industry. Jobsite technologies can only communicate when they follow shared protocols, and that interoperability is what turns isolated tools into a unified system. Many leading firms are now building custom integrations so that data from drones, telematics, and accounting software all merge into one digital record. This single source of truth provides executives, project managers, and field crews with synchronized visibility from estimating to final handoff.

The deeper value of this digital transparency lies in learning. Every completed project becomes a case study of what worked and what didn’t. By comparing live data from multiple jobs, companies can identify which crews outperform, which clients yield the highest margins, and which equipment delivers the best return. This knowledge feeds continuous improvement in a way that intuition alone never could. The connected jobsite becomes an evolving organism, learning from every decision to make the next project more efficient than the last.

AI, Predictive Analytics, and Smart Equipment in Construction

The next leap in connected jobsite technology is being driven by artificial intelligence and predictive analytics. What began as digital recordkeeping has evolved into proactive management powered by machine learning. Construction companies that once reacted to issues are now forecasting them with startling accuracy. The result is a new level of control over time, cost, safety, and quality that fundamentally changes how jobs are planned and executed.

Artificial intelligence is the brain behind this transformation. It takes the mountains of data collected from sensors, drones, and field apps and turns it into clear, actionable insight. Instead of simply showing what happened yesterday, AI reveals what will likely happen tomorrow. Predictive models analyze weather patterns, crew productivity, material availability, and historical performance to forecast delays or budget risks before they occur. This allows project managers to act rather than react—to reassign crews, reorder materials, or adjust timelines while there is still time to prevent loss.

One of the most practical uses of AI in construction is predictive maintenance. Equipment no longer breaks down without warning. Telematics systems capture every vibration, temperature spike, and runtime anomaly, and AI translates those readings into maintenance forecasts. Contractors can schedule service at optimal intervals rather than waiting for failure or wasting resources on unnecessary checks. The savings from reduced downtime are immense, but the greater value lies in reliability. Projects move without interruption, and clients notice the difference in consistency and professionalism.

Smart equipment also plays a central role in this evolution. Modern excavators, cranes, and graders are now semi-autonomous, operating with digital precision that adjusts to site conditions in real time. Machine control systems use AI to interpret design files and automatically calibrate the blade, bucket, or lift to the exact slope or grade required. This ensures accuracy on the first pass, minimizing rework and fuel waste. The operator’s role shifts from manual control to guided supervision, allowing even mid-level operators to deliver expert-level results through intelligent assistance.

Predictive analytics also reshapes project planning at the organizational level. By examining historical job data—crew performance, material waste, weather delays, and client behaviors—AI systems identify patterns that humans might overlook. For example, a contractor may discover that certain types of projects consistently yield higher margins in specific regions or that certain clients tend to trigger more change orders. These insights influence bidding strategy, helping companies pursue the most profitable opportunities while avoiding risky contracts. Over time, data-driven decision-making replaces gut instinct as the foundation of business growth.

Safety, one of the most critical areas of construction, is also being enhanced through AI. Wearable devices now monitor worker movement, posture, and environmental conditions, sending alerts when fatigue, heat, or unsafe proximity is detected. Cameras equipped with AI can recognize unsafe behaviors—like missing PPE or unauthorized access to restricted zones—and instantly notify supervisors. These systems are not designed to police workers but to protect them, providing early warnings that save lives. The technology sees what the human eye might miss in the chaos of a busy site.

Even scheduling is being reimagined through AI. Instead of static timelines that quickly fall outdated, predictive scheduling engines update themselves automatically. When weather forecasts change or deliveries are delayed, the system recalculates the schedule, updates dependencies, and sends notifications to affected teams. This continuous recalibration ensures that projects stay aligned with real-world conditions, not just the assumptions on paper.

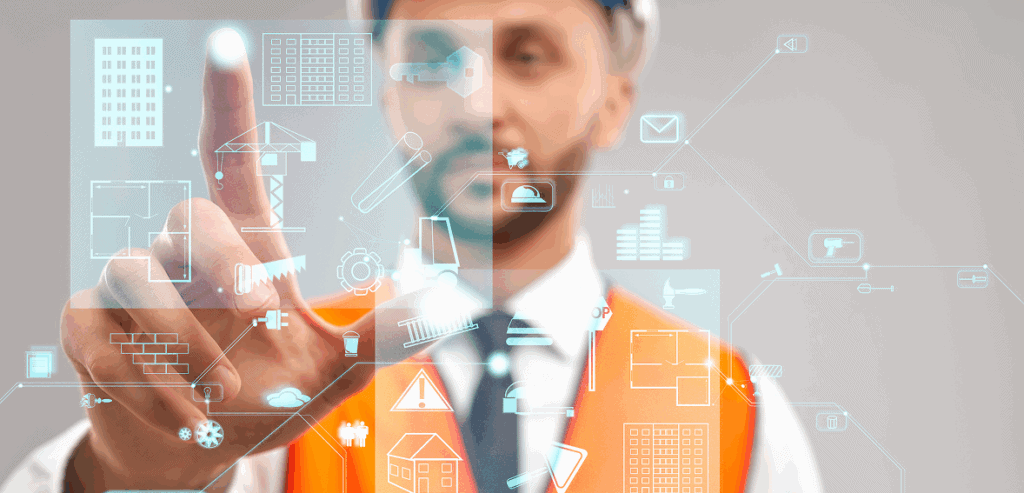

The combination of AI, predictive analytics, and smart equipment forms the foundation of what industry leaders call “Construction 4.0.” It is a fully digitized, interconnected, and intelligent construction environment where machines, materials, and people share information in real time. In this world, decisions are based on truth, not estimates; on forecasts, not hindsight. The contractor who masters this ecosystem gains a level of foresight and precision that was impossible just a few years ago.

The future of the industry will not be defined by who has the most powerful tools, but by who uses their data most intelligently. As predictive systems continue to evolve, contractors will gain the ability to simulate entire projects before a shovel hits the ground—testing sequences, logistics, and budgets virtually. The winners in this new era will be those who treat information as their most valuable asset, building not just with concrete and steel, but with insight.

Building the Fully Integrated Jobsite — Linking People, Equipment, and Data

The most advanced contractors are no longer experimenting with individual apps or isolated sensors—they are building complete ecosystems. The fully integrated jobsite connects every digital element into a single intelligent network. When people, equipment, and software exchange information automatically, construction becomes faster, safer, and vastly more predictable. Integration is not simply about technology; it is about turning fragmented processes into one continuous flow of insight from the field to the office.

Why Integration Matters

- Integration closes the communication gap that has always existed between field operations and office administration. In the past, data from equipment telematics, daily reports, and payroll lived in separate silos, forcing managers to compare numbers manually. A unified system merges those inputs into a live dashboard, showing hours worked, materials used, and cost impact in real time. This visibility eliminates lag and allows decisions to be based on today’s facts instead of last week’s reports.

- A connected environment also strengthens accountability. When information flows automatically, there is no room for selective reporting or lost paperwork. Every crew, machine, and task produces digital evidence of progress. Managers can verify claims instantly, and clients gain transparency that builds trust. Disputes fade because the record speaks for itself.

- Integration creates resilience. When schedules, budgets, and resources are linked through cloud systems, a disruption in one area triggers automatic updates in others. A late delivery or equipment breakdown instantly adjusts crew assignments and cost projections. Instead of scrambling to recover from delays, the system helps teams adapt before productivity suffers.

Real Examples of Integration in Action

| Integration Type | Primary Connection Made | Resulting Efficiency Gain | Example Platform |

|---|---|---|---|

| Field Apps ↔ Accounting Software | Labor hours and expenses sync directly to job costing | Eliminates manual entry and payroll errors | Buildertrend + QuickBooks |

| Telematics ↔ Maintenance Scheduling | Equipment data feeds service alerts to fleet management | Reduces downtime and extends machine life | Caterpillar VisionLink + Fleetio |

| Drones ↔ Project Management | Aerial progress data links to schedules and drawings | Provides visual proof of percent complete | DroneDeploy + Procore |

| BIM ↔ Field Layout Robots | Digital design files guide robotic layout equipment | Improves accuracy and reduces rework | Trimble Connect + Spot Robot |

| Safety Sensors ↔ Incident Reporting | Wearables send alerts into safety dashboards | Enables instant response and prevention | Halo Smart Sensor + Safesite |

Insights from Connected Jobsite Adoption

- Integrated data flows have proven to reduce total project administration time by as much as twenty-five percent. The elimination of redundant entry and cross-checking frees managers to focus on forecasting instead of paperwork. Companies that once employed entire departments for manual data processing now repurpose that labor toward quality assurance and client service.

- The value of integration grows exponentially with scale. Each additional project or crew that joins the system multiplies the insights available. When data from multiple jobs feeds one central platform, trends emerge—equipment utilization rates, regional weather impact, subcontractor reliability, and supplier performance. Those analytics fuel better planning and strategic purchasing decisions that improve margins company-wide.

- Integration also strengthens safety culture. When sensors, reports, and video monitoring connect automatically, unsafe trends are identified before incidents occur. Managers receive alerts when heat exposure rises or when proximity sensors detect a near miss. Instead of reacting after an accident, they intervene proactively.

- The cultural side of integration cannot be overstated. Teams must see technology as a shared language rather than a management tool. Field workers provide the raw data, but that data only gains meaning when the office interprets and acts on it. Successful firms build routines around daily syncing, open dashboards, and regular training so everyone understands how their input shapes company performance.

- Over time, an integrated jobsite evolves into a digital command center. From a single login, leadership can view progress photos, approve invoices, monitor fuel burn, and compare cost performance across multiple regions. The business becomes transparent to itself. That clarity turns chaos into coordination and turns guesswork into measurable improvement.

Integration as a Competitive Edge

The future of construction belongs to the contractors who connect, not just collect. Isolated technology creates islands of efficiency; integrated systems build continents of insight. When every machine, tool, and person becomes part of one ecosystem, the contractor gains an almost unfair advantage. Jobs finish faster, clients receive clearer updates, and profits become consistent rather than circumstantial.

Integration does not require the largest budget—only commitment. Starting small with two or three linked systems can deliver immediate results. The key is to design the workflow deliberately so data moves effortlessly from the field to the boardroom. Once that flow is established, growth becomes self-sustaining, and technology stops being an experiment and becomes the heartbeat of the company.

The Future of Construction Technology — AI Collaboration and Sustainability in the Next Decade

The coming decade will redefine how construction operates, not because of new machines, but because of new intelligence. Artificial intelligence, automation, and sustainability will merge to create an ecosystem where data, materials, and people work in harmony. The industry is shifting from reaction to prediction, from repetition to automation, and from waste to optimization. The connected jobsite will no longer be a goal—it will be the default.

Artificial intelligence will evolve from analyzing performance to actively managing operations. Systems will not just suggest schedule changes; they will implement them automatically. Procurement tools will order materials when inventories run low, adjusting quantities based on updated job progress. AI assistants will forecast labor demand, reassign crews, and even negotiate subcontractor terms using predictive cost models. The construction office of the future will function like an air traffic control center, where human leaders oversee automated coordination rather than chase manual tasks.

Sustainability will sit at the heart of this transformation. Smart sensors and data platforms will measure carbon footprints in real time, giving contractors visibility into their environmental impact. Machines will optimize fuel consumption, select the most efficient routes, and idle only when necessary. Material tracking systems will verify the origin, usage, and recycling rate of every component. Green construction will stop being a niche—it will become the competitive standard. The clients of tomorrow will demand transparency, and technology will provide it with precision.

Robotics will continue to take on more physical tasks, especially in repetitive or hazardous environments. Autonomous drones will handle surveys, deliveries, and inspections with minimal oversight. 3D printing robots will fabricate components on-site, reducing waste and transportation costs. These automated systems will shorten project timelines dramatically while maintaining a higher degree of accuracy than traditional manual processes.

The evolution of collaboration will be equally profound. Augmented and virtual reality will bridge the gap between design and execution. Teams will walk through virtual models before construction begins, identifying conflicts and changes in a shared digital space. This collaboration will eliminate much of the rework that currently consumes time and budgets. Owners, architects, engineers, and contractors will work from the same live model, updating and approving changes instantly.

The future jobsite will resemble a coordinated digital organism. Every element—workers, machines, and materials—will feed data into a central intelligence. The system will understand patterns, anticipate needs, and guide decisions without requiring constant human supervision. The contractor’s role will evolve from directing labor to managing intelligence. Efficiency, safety, and sustainability will no longer compete with one another; they will coexist naturally within the same digital framework.

What once required decades of experience will soon be accelerated by intelligent assistance. The essence of craftsmanship will remain, but the process will be smarter, cleaner, and more predictable. The firms that embrace this transformation early will not just survive—they will define the next generation of construction excellence.

Connected Jobsite Technology and Smart Construction Tools

Q1: What is a connected jobsite, and how is it different from a traditional one?

A connected jobsite links workers, equipment, and management systems through digital communication and real-time data. Unlike traditional sites that depend on paper reports and phone updates, a connected jobsite provides instant visibility into schedules, costs, and safety conditions. It reduces errors, speeds up decisions, and ensures everyone—from field crews to executives—operates from the same live information.

Q2: Is connected jobsite technology only for large contractors?

Not at all. Many of the most impactful tools—such as mobile field apps, telematics, and time-tracking systems—are affordable and scalable for small and mid-sized contractors. Modern software is cloud-based, meaning a two-crew company can access the same level of insight that a national firm does. Integration, not size, determines success.

Q3: How expensive is it to implement these systems?

The initial cost varies depending on the number of users and integrations, but the return on investment is clear. Contractors typically recover setup expenses within a few projects through reduced rework, faster billing, and lower idle time. Subscription-based pricing also allows companies to scale up gradually instead of paying large upfront costs.

Q4: What happens if there’s no strong internet connection at the jobsite?

Many field tools work offline and sync data automatically once a connection is restored. In remote areas, portable Wi-Fi units or mesh networks can establish temporary connectivity. The key is planning ahead—ensuring your site has at least one reliable channel for uploading essential data daily.

Q5: How does technology improve jobsite safety?

Wearable sensors, drones, and AI-driven cameras now detect unsafe conditions before accidents occur. These systems alert supervisors to issues such as excessive heat, fatigue, or proximity to moving equipment. Beyond monitoring, digital safety reporting helps companies track patterns and address recurring risks before they lead to incidents.

Q6: What role does artificial intelligence play in construction today?

AI has moved from being a futuristic idea to an everyday operational asset. It analyzes past project data to predict future performance, identifies risk factors that humans might overlook, and automates repetitive office tasks like scheduling or reporting. Its value lies in decision support—helping managers act faster and with more confidence.

Q7: How can contractors encourage their teams to adopt new technology?

The best results come when leadership sets the example. When superintendents and managers use the tools consistently, field teams follow naturally. Training should focus on how technology makes life easier—less paperwork, faster communication, more accurate pay. Once crews see the benefits firsthand, adoption becomes self-sustaining.

Q8: What’s the future of construction technology?

The next era will merge automation, sustainability, and intelligence. Projects will be planned with predictive AI, executed with robotics, and verified with real-time environmental data. Contractors will manage integrated ecosystems where safety, productivity, and profitability align seamlessly. The winners will be those who use information as a tool of craftsmanship, not just administration.

Closing Thoughts: The Blueprint for the Future Contractor

The construction industry is standing at the edge of a new industrial revolution. The jobsite of tomorrow will be measured not only by physical output but by the precision of its data. The most successful contractors will combine skill, strategy, and software into a unified operation that never stops learning.

Connected technology does not erase the human element—it enhances it. The intuition of an experienced foreman, the insight of a project manager, and the leadership of a business owner all become sharper when powered by real-time information. Machines can measure and predict, but people still decide how to build. The goal of digital transformation is not to replace the builder; it is to empower the builder with perfect clarity.

In the end, the firms that thrive will be those that understand a simple truth: information is the new toolbelt. The contractors who wear it well will construct not just buildings, but a smarter, safer, and more profitable future for the entire industry.